Market – leading Ansys Granta products have been developed over years to ensure capture, safeguard and capitalize on the organization’s material Intelligence. It offers a scalable solution to create, control and store your company's valuable material data, offering seamless integration with leading CAD, CAE and PLM systems for enterprise-wide consistency. Ansys helps businesses digitalize their company’s materials knowledge, choose the right materials for their products, and provide resources for materials education.

|

Product

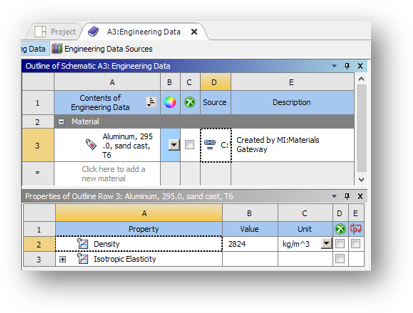

CAD, CAE and PLM Integration, Assess Restricted Substance Risk, Access 250,000+ Material, Support Additive Manufacturing, ‘Gold Sources’ for Materials Data Integration across CAD and CAE, User – friendly Materials database, 700+ Materials Datasets Pre – loaded, Compare Materials Properties Intelligent Materials selector, Comprehensive Materials Data, Find Similar Materials, Export simulation – ready Data Trusted materials Data, Wide Spectrum of data, Granta Software Ready, Complete and comparable Trusted Data, Simulation – ready material model, Easy Access Comprehensive database of materials and processes, Powerful visualization and selection tools, Introduce sustainability in Engineering Design,Interactive Projects, exercises and lecturers |

|

Capabilities

Enabling digital transformation: Boosting simulation accuracy: Smarter materials choices: Fully integrated: Faster to market: Repeatable additive manufacturing: Ensure regulatory compliance: Visibility across the product value chain: |

|